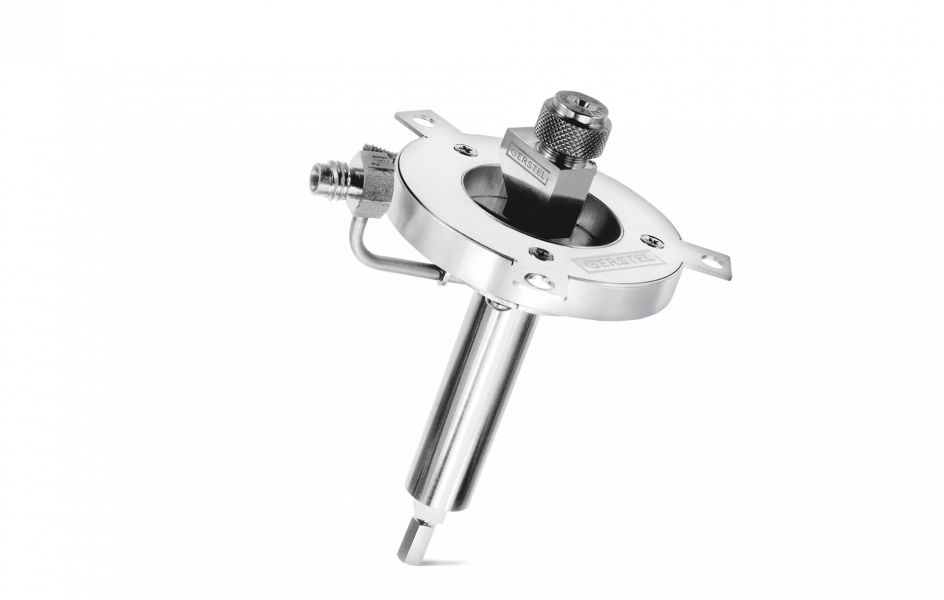

Cooled Injection System CIS

The universal septumless inlet for all injection techniques used in GC and GC/MS analytics.

The Cooled Injection System CIS is a universal inlet for all injection techniques used in GC and GC/MS analytics. In addition to conventional split/splitless injection, it also allows on-column injection and cooled injection to be performed. The CIS impresses due to its full temperature control and its unique septumless head SLH. The CIS can be combined with additional GERSTEL modules and therefore forms the basis for a multitude of applications. The operation of the CIS can be automated using the MultiPurposeSampler MPS. The system is controlled using the MAESTRO software.

Functional principle of the CIS

When carrying out cooled injection using the CIS, the sample is first injected into the liner in the cold CIS and is collected there. The CIS then heats up, the sample is vaporized and the analytes are transferred to the column along with the gas stream. Sample introduction is performed in accordance with a temperature program. The temperatures and gas flows within the system can be adjusted individually.

At the time of injection, the needle enters the SLH that closes off the CIS at the top. The needle slides a movable sealing body out of the insertion channel and the sample enters the CIS. When the needle is withdrawn, the sealing body seals the insertion channel again. The system is sealed off from the external environment for the entire time the injection is being performed.

Benefits

During sample introduction, you have full control over the temperature program and pneumatic program. Depending on requirements, the sample can be gently heated or explosively vaporized. This means that even components with a higher boiling point and thermally sensitive substances can largely be transferred without discrimination. You can either transfer the sample to the column in full (splitless mode) or proportionally (split mode).

The unique septumless head SLH prevents incorrect analysis results that arise due to septum bleeding or septum particles. You can use the CIS to enrich analytes resulting from an upstream sample preparation step, thereby increasing the sensitivity of the system as a whole. Solvent venting or on-column injection are also possible. Thanks to the MAESTRO software, controlling the system as a whole is simple and intuitive.

Variants

The CIS 4 was designed to enable rapid sample introduction at temperatures of up to 450 °C. The CIS 6 allows sample introduction within the high temperature range.

Options

The ALEX option enables the liner to be changed automatically using the MPS

Downloads

The automated lines exchange ALEX option enables the liner to be changed automatically using the MultiPurposeSampler MPS. The changing of the liner can be incorporated at any point within the run, as required. The number of liner changes is also freely selectable. The system is controlled using the MAESTRO software. Within the software itself, all preparation steps can be prepped ahead to save time.

Functional principle of the ALEX option

The CIS is fitted with a special head and the liners are fitted with transport adapters. The liners are stored in a tray and are kept free from contamination. To perform a liner change, the head is pneumatically unlocked. The MPS removes the used liner from the CIS and places a fresh liner inside the CIS. The head is then locked again. The system is ready for sample introduction.

Benefits

Samples containing a matrix can be analyzed without special sample preparation, as soiled liners are changed during the run. The fact that no time-consuming liner changes are required means that the system is used in the most efficient possible manner. During the course of a run, you can use liners with different properties, for purposes such as method development, for example. Thanks to the MAESTRO software, controlling the system as a whole is simple and intuitive.

Downloads